The Development of Our Custom Products

From idea to product

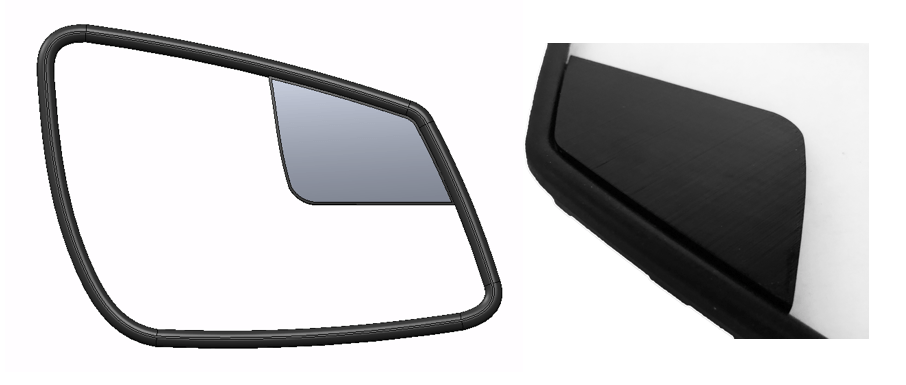

The development process begins by conceptualizing the design for an OEM-like fit. Our team evaluates a number of factors unique to each specific make and model to determine the proper form and function.

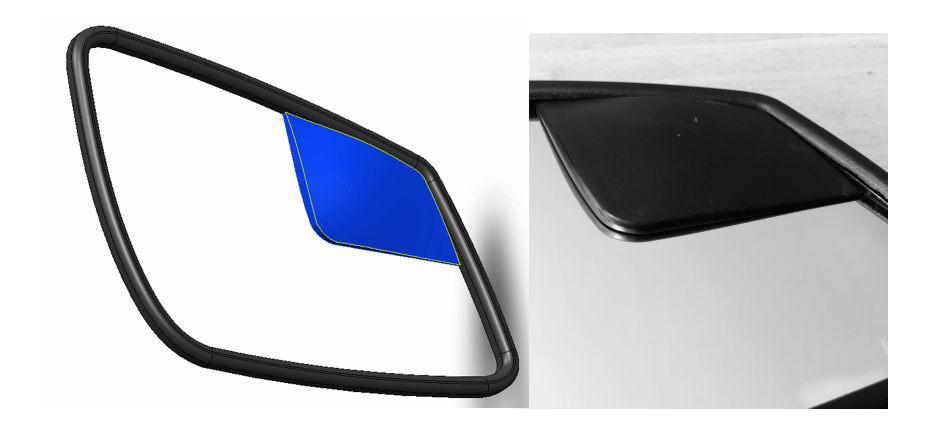

Perfecting the functionality and fitment

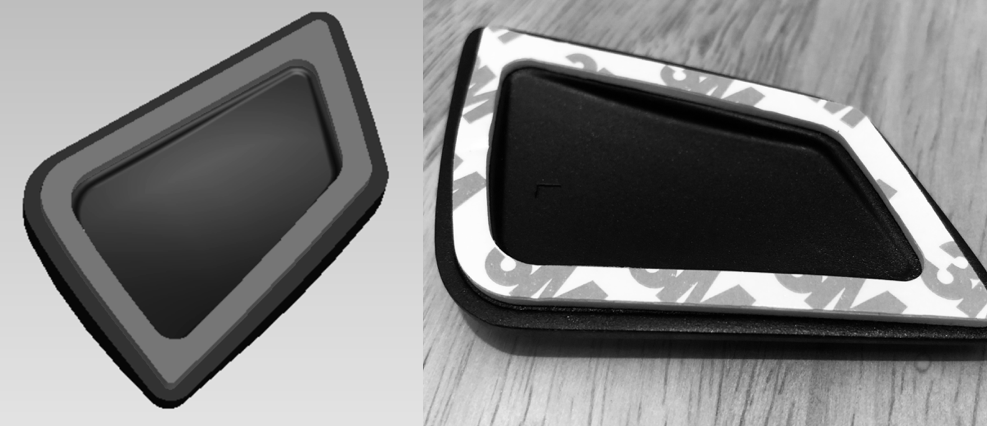

Once a design has been formalized, 3D printing or handmade prototypes are created to test the fitment and functionality.

In order to provide the best possible product, this part of our process can involve as many as 6 or 7 prototype revisions to achieve the best possible product.

Real world testing

Before our team starts to produce a new product, a production prototype is created and thoroughly road tested in various conditions.

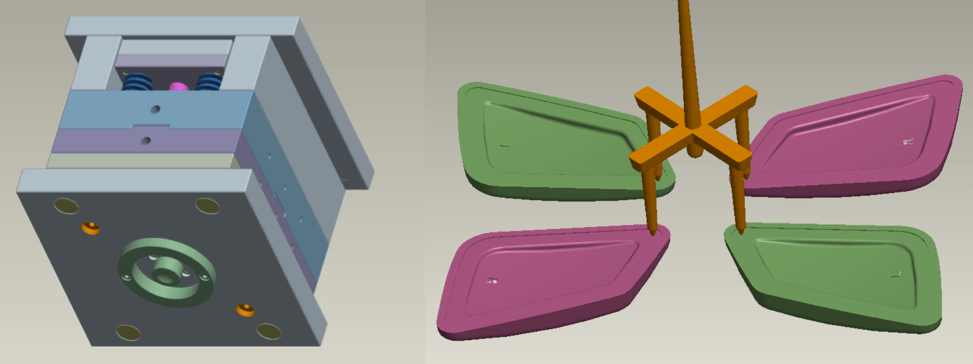

Tooling and production

Upon completion of our exhaustive development process, it is time to begin the production process. Our primary methods are injection molding, die-cutting and laser cutting to produce our products.

Ready to shop?

Click Now!

Store